Services

Electrical appliances are an integral part of our daily lives. Ensuring their safety is paramount, not just for the device’s longevity but, more importantly, for human safety. Enter the realm of “test and tag”, a procedure that guarantees the safety of portable electrical appliances.

-

RESIDENTIAL Services

Testing and tagging for residential premises are a specialty for LC electrical.

What is Test and Tag?

Testing and tagging is a two-fold process. It begins with a visual inspection of the appliance for any signs of damage. This is followed by an electrical test using a Portable Appliance Tester (PAT). Once an item clears these checks, it’s tagged, indicating its tested status, the tester’s details, test date, and the next due date for testing.

Purpose of Test and Tag

The primary objective behind this procedure is to ensure the safety of individuals using or coming into contact with the appliance. It significantly reduces the risk of electrical hazards. In the unfortunate event of an accident involving an untested appliance, the employer might be held liable.

Importance of Safety

Safety isn’t just a word; it’s a responsibility. In workplaces, where multiple electrical appliances are in use, the risk factor multiplies. Regular testing and tagging act as a preventive measure, ensuring that any potential hazards are identified and rectified before they escalate.

AS/NZS 3760 Standard for TEST AND TAG

This is the guiding light for the tagging industry in Australia and New Zealand. It provides comprehensive guidelines and regulations concerning the electrical safety of appliances. The standard underwent an update in 2022, now known as AS/NZS 3760:2022, introducing various changes.

Who Needs to Test and Tag?

Certain industries, due to their nature, require frequent testing. For instance, sectors like construction, demolition, and mining mandate testing every three months. However, outside these industries, while there’s no legislative compulsion, the onus lies on the employer to ensure the safety of all portable electrical appliances.

Who Can Perform These Tests?

Contrary to popular belief, you don’t have to be an electrician. As per AS/NZS 3760:2022, a ‘Competent Person’ can also perform these tests. This competency is often achieved by attending a test and tag course, equipping individuals with the necessary skills. However, if you want the added extra of guaranteed tests, it’s best to have one of our electricians to do the testing. Electricians have to undergo extensive training so you know you’re in the right hands.

Equipment for Test and Tag

The range of equipment that falls under this procedure is vast. Any device with a flexible cable and a removable plug that isn’t low voltage (exceeding 50V) needs testing. This includes items like extension leads, cord sets, and portable RCDs.

Frequency of Testing

The testing frequency largely depends on the environment where the appliance is used. While construction sites might require quarterly checks, a warehouse might have bi-annual tests.

Portable Appliance Tester (PAT)

A PAT is the hero of the test and tag process. It’s the primary equipment used to test an appliance’s safety. Several factors influence the choice of a PAT, from budget considerations to functionality needs.

Visual Inspection

Before any electrical testing begins, a visual inspection is crucial. Interestingly, most defects or faults are identified during this phase, even before the PAT comes into play.

FAQs

What is the main purpose of test and tag?

It ensures the safety of portable electrical appliances, reducing electrical hazards.

Is it mandatory for all industries?

No, but industries like construction and mining have stricter regulations.

Who can perform these tests?

Either an electrician or a ‘Competent Person’ trained in test and tag procedures.

How often should appliances be tested?

It varies based on the appliance’s environment and individual risk assessments.

What is a PAT?

A Portable Appliance Tester, the primary equipment used in the test and tag process.

Is visual inspection necessary?

Yes, it’s the first step and often identifies most defects.

Conclusion

The procedure is more than just a safety protocol; it’s a commitment to ensuring that workplaces and homes are free from electrical hazards. By understanding its importance and ensuring regular checks, we can create a safer environment for all.

Looking to ensure your safety compliant with a reliable Victorian company?

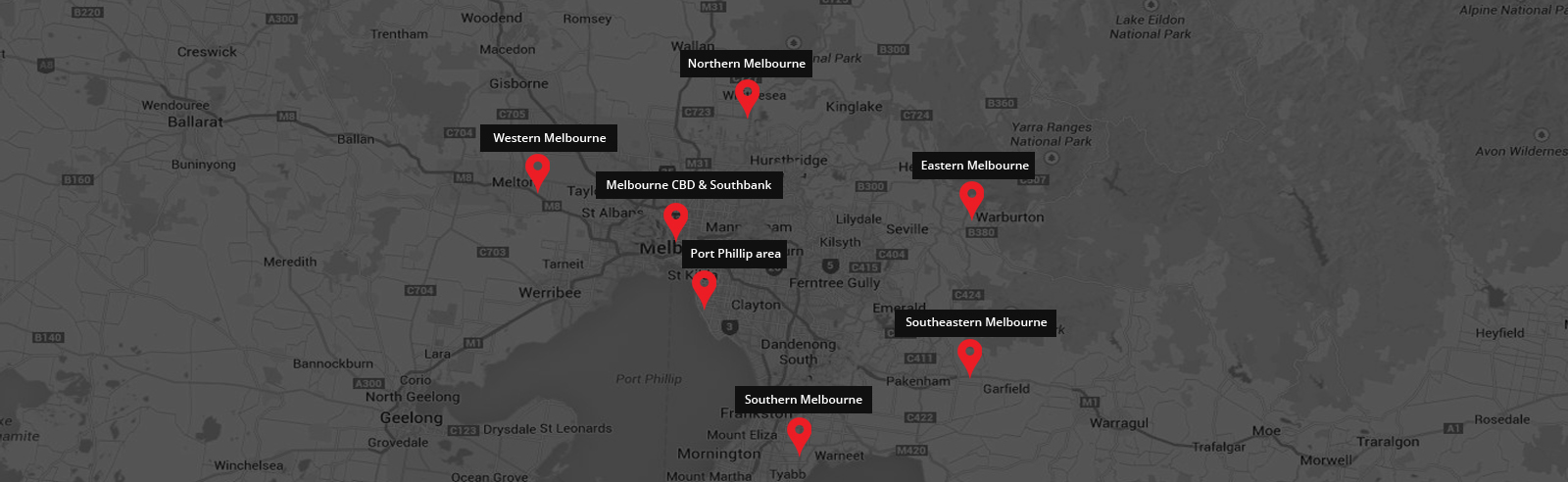

We service locations in Victoria, Australia.

Welcome to LC Electrical Services

LC Electrical Services is a business that through clear and transparent communication, delivers quality electrical services and solutions that are in line with client’s requirements and expectations. Our installation and maintenance expertise along with our proven reputation makes us a trusted contractor to the most prominent builders, business owners, private clients and project managers in the Melbourne Metropolitan area. We have a progressive and experienced team who whilst